Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Lightweight design and performance of U-TR...

Lightweight design and performance of U-TR...In the field of high speed automated mechanical equipment, the performance and light weight of the core drive compone...

Detailed instructions Send mail -

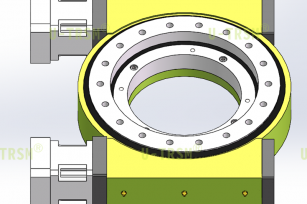

Analysis of lightweight double gear slew d...

Analysis of lightweight double gear slew d...Core Design Advantages In response to the core demands of limited installation space for automated rotating pl...

Detailed instructions Send mail -

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

-

Brief analysis of gear safety factor of spur gear slewing drive

Publish time:2024-02-24The service life of spur gear slewing drive is a common concern for customers and it is also a common issue that our engineers need to consider during the design phase. If you want the slewing drive to be safe and durable, the first consideration is the safety factor, which requires safe output torque and load within specified conditions. In thi...

-

What are the advantages of using planetary gearboxes for slewing drives?

Publish time:2024-01-26During the design process of slewing drives, U-TRSM design engineers often encounter the requirement of increasing the gear ratio and torque, which allows them to choose smaller motors, saving installation space and costs. In the adaptation of gearboxes, U-TRSM design engineers recommend the use of planetary gearboxes because they have the follo...

-

Advantages of using spline connection for slewing drives

Publish time:2024-01-19In the design process of slewing drives, sometimes spline connections are used. What are the advantages of using spline connections? 1. More teeth, strong load capacity: The number of teeth of the involute spline is more, the teeth root has high hardness and can withstand larger loads, the more teeth can distribute the transmission of lar...

-

How to correctly choose bolts for installing the slewing drive?

Publish time:2024-01-15The installation of the slewing drive is usually fixed by bolts, and only by selecting bolts of the correct strength level can the safe and stable operation of the slewing drive be ensured. So how can we choose the right bolt? Here, our engineers will introduce some factors that should be considered when choosing bolts. 1. Different appli...

-

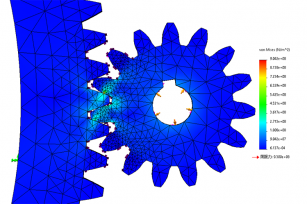

Introduction to the advantages of finite element analysis for gear meshing design

Publish time:2024-01-15The U-TRSM design engineers have rich experience and technology in the field of non-standard design, often using finite element analysis to achieve the desired design results. Finite element analysis is a powerful numerical analysis tool that has significant advantages than the traditional methods (commonly known as “beating the head”...

-

Analysis of the influence of sliding speed of worm on transmission efficiency in slewing drives

Publish time:2024-01-15In the design of worm gear slewing drives, U-TRSM design engineers often have to consider many factors, including the sliding speed of the worm, which has a significant impact on the transmission efficiency of the worm. In the design process, comprehensive considerations and adjustments should be made based on specific needs. Here is a brief ana...

-

Advantages and disadvantages of double lead worm in slewing drive

Publish time:2023-12-28In some non-standard worm gear and worm design, for high precision and high efficiency working conditions, the design engineers of U-TRSM will recommend the double-lead worm design. So what are the advantages and disadvantages of double-lead worm in use? Please see the following: 1. High efficiency, double-lead worm has a larger tooth con...

-

How to improve the torque of worm gear and worm in slewing drive

Publish time:2023-12-28In the process of designing slewing drives, U-TRSM design engineers often come across standardized slewing drives with the same size and space constraints that do not meet the performance parameters of the customer’s application. So in this situation, how to improve the torque and other parameters of the worm gear and worm in slewing drive...

-

Deformation control of slewing drive housing casting

Publish time:2023-12-16When designing slewing drive products, U-TRSM design engineers often encounter non-standard designs, such as casting the housing and the equipment base as one piece, extending the housing outside to increase the location of the mounting holes and other ways. So in the housing casting, the reasonable design of wall thickness, bottom plate, rib pl...

-

Why is it not recommended to repair the gear after quenching and fracture in the slewing drive

Publish time:2023-12-07U-TRSM engineers are also involved in many processes during the production and machining of slewing drives and provide timely optimisation and feedback on details in order to design and produce quality products. As an accessory in a slewing drive, tooth hardening is a very critical process in the production of slewing bearings. Cracks may appear...

-

Arrangement method of bolts when mounting the slewing drive

Publish time:2023-11-07U-TRSM designers often encounter non-standard designs and custom slewing drives in the design of slewing drives. The connection methods of slewing drive rely on bolts, so the number and size of bolts play a crucial role. The position of each bolt should ensure that the force on each bolt is uniform and small, avoiding additional loads on the bol...

-

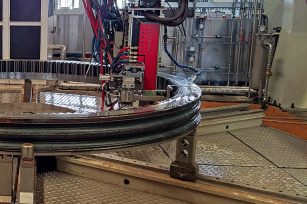

High speed double input copper worm gear slewing drive

Publish time:2023-08-26Unique Transmission Equipment (Luoyang) Co., Ltd. has designed a high precision double input high speed slewing drive for customers, which is used on automation equipment. Slewing drive adopts 0 clearance design to ensure the stability and accuracy in use, double input design greatly eliminates tooth backlash. Our customers use two servo motors ...