Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Lightweight design and performance of U-TR...

Lightweight design and performance of U-TR...In the field of high speed automated mechanical equipment, the performance and light weight of the core drive compone...

Detailed instructions Send mail -

Analysis of lightweight double gear slew d...

Analysis of lightweight double gear slew d...Core Design Advantages In response to the core demands of limited installation space for automated rotating pl...

Detailed instructions Send mail -

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

Introduction to the advantages of finite element analysis for gear meshing design

Publish time:2024/01/15 News Views:291

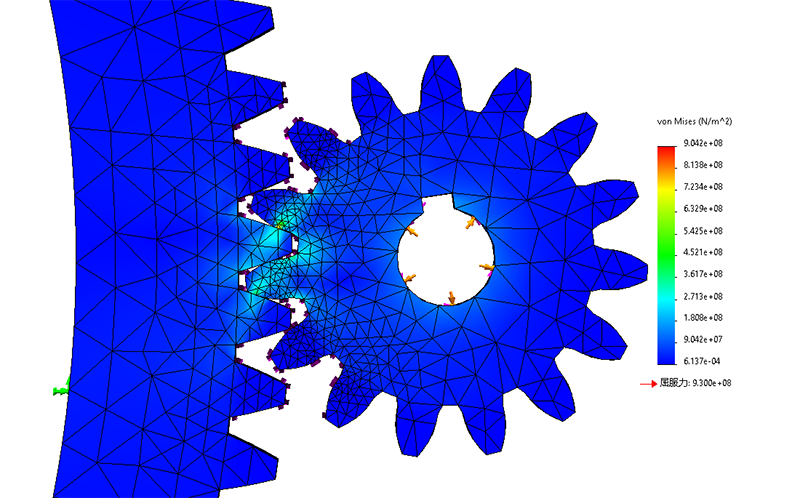

The U-TRSM design engineers have rich experience and technology in the field of non-standard design, often using finite element analysis to achieve the desired design results. Finite element analysis is a powerful numerical analysis tool that has significant advantages than the traditional methods (commonly known as “beating the head”, involving a lot of tedious mathematical calculations) in the field of gear meshing.

1. Accuracy: Finite element analysis can accurately simulate the mechanical properties of gear meshing, taking into account various complex factors such as lubrication friction, contact conditions, material line types and external operating conditions.

2. Flexibility: Finite element analysis is a commonly used method that can be used to study various types of gear meshing conditions, such as the parameter design of gears, the transmission system integrity and the noise and vibration generated.

3. Efficiency: Finite element analysis is an efficient and fast calculation method using computers, which greatly improves design efficiency. Of course, the configuration of the computer is crucial.

4. Visualization: Finite element analysis can generate various graphics and icons, such as stress distribution diagrams, strain force distribution diagrams, contact pressure distribution diagrams, etc. These icons are the basis for designers to better understand the meshing behavior of the gears.

5. Optimization design: Finite element analysis can be used to optimize gear meshing design, by simulating and analyzing various design schemes to find the optimal design, improving the performance and life of the gear.

- Application of slew drive for solar tracker

- The importance of the difference between t...

- Which industries and equipment can the sle...

- Spur gear slew drive housing select nodula...

- Influence of rotational inertia on the sle...

- Analysis of the influence of sliding speed...

- How should the slewing drive be maintained?

- What is the cause of the slewing ring damage?