Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail -

30855 slew drive assembly: precise protect...

30855 slew drive assembly: precise protect...Introduction In the field of industrial transmission, U-TRSM has always been a leader in innovation, committed...

Detailed instructions Send mail -

High load slewing drive solution for deep ...

High load slewing drive solution for deep ...This slewing drive is used in marine machinery and equipment, suitable for underwater locations at depths of up to 30...

Detailed instructions Send mail

Technical analysis of slewing bearing material (42CrMo)

Publish time:2021/08/04 News Views:788

Large slewing bearings and high precision slewing bearing rings are generally made of alloy structural steel 42CrMo, which has good mechanical properties, high strength and toughness, after being tempered (Q+T), it has the characteristics of fatigue resistance, impact resistance and good low-temperature impact toughness. Let’s get to know this high quality material.

42CrMo Chemical composition

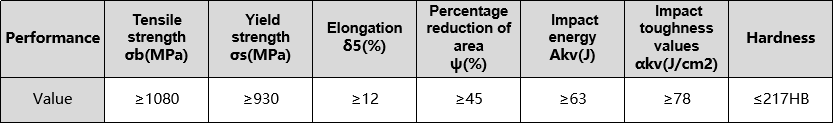

42CrMo Mechanical property

After rough machining of 42CrMo, it is usually quenched and tempered. the ideal ring hardness can be obtained through quenching and tempering, improve the comprehensive mechanical properties, a reasonable tempering technology can obviously improve the material’s comprehensive mechanical properties and yield strength, give full play to the material potential performance, ensure the material performance when used and extend the service life. Tempering is the process of quenching + high temperature tempering. Usually, the quenched and tempered hardness of the slewing bearing is HB229-269, which can also be adjusted according to the actual situation. Let’s understand the tempering technological parameters.

The comprehensive mechanical properties of the tempered 42CrMo have been improved and the hardness has also reached the standard requirements. The slewing bearing ring under the hardness of HB229-269, the hole processing and tooth processing are relatively easy, if the hardness exceeds HB300, hole machining and tooth machining require special machining methods. Conventional machining methods are too inefficient, wind turbine bearings usually require high hardness in order to meet the requirements of low-temperature impact energy.

42CrMo is suitable for surface quenching to achieve a higher hardness, which can improve the slewing bearing load capacity and wear resistance, can also increase the slewing bearing service life. In addition to surface quenching to achieve the required hardness, it must also achieve the required hardened layer depth, if the hardened layer is not deep enough, the load capacity will decrease and premature damage will occur. People usually don’t understand why the tempered hardness is low in or the hardened layer is not deep enough, the load capacity will decrease. Let us give an example as below:

For example, comparison 1, the wooden board above is equivalent to hardened layer, the cement and sand below are equivalent to the tempered slewing bearing ring, if the hardened layer depth is same, the tempered ring is one hard and the other soft, it’s like wooden boards with the same thickness pressed on the cement and sand, obviously the wooden board on the cement bears higher load, because of its hard foundation, it can provide good support, so the slewing bearing ring tempered hardness can’t be lower than the standard, otherwise it will affect the slewing bearing load capacity.

For example, comparison 2, thick wooden board is equivalent to deep hardening layer, thin wooden board is equivalent to shallow hardening layer, put both thick board and thin board on the sand, obviously thick board carry more load.Because thick wooden board is stronger, the hardened layer depth can’t be lower than the standard, otherwise it will affect the slewing bearing load capacity.

Therefore, the tempering hardness, quenching hardness and hardened layer depth of the slewing bearing are very important for the slewing bearing load capacity. The internal technical requirements of these important slewing bearings must meet the standards. Materials and heat treatment are very important to the slewing bearing, therefore, the heat treatment quality must be strictly controlled during production and processing to provide conscientious products to customers.

- Analysis Of Five Brake Locking Devices Dri...

- How to measure the slewing ring diameter?

- Analysis of the casting method of the slew...

- Force rational design of integrated slewin...

- What matters should be paid attention to w...

- Gear transmission noise: problem analysis ...

- What is the impact of gear displacement de...

- Advantages and disadvantages of double lea...