Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Lightweight design and performance of U-TR...

Lightweight design and performance of U-TR...In the field of high speed automated mechanical equipment, the performance and light weight of the core drive compone...

Detailed instructions Send mail -

Analysis of lightweight double gear slew d...

Analysis of lightweight double gear slew d...Core Design Advantages In response to the core demands of limited installation space for automated rotating pl...

Detailed instructions Send mail -

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

-

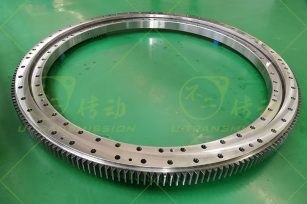

A qualified slewing bearing requires a lot of people’s efforts

Publish time:2021-07-28Slewing bearing production and manufacturing generally follow this order: forging-tempering-turning-quenching-gear machining-matching clearance-assembly and delivery. The manufacturing of slewing bearings requires lathes, gear machining equipment, quenching equipment, grinders, etc. Everyone often sees these equipments and they are all familiar ...

-

How to improve the service life of slewing bearings of large mechanical equipment?

Publish time:2021-07-28Slewing bearings play an important role in large machinery and equipment as transmission components. Slewing bearings for large machinery and equipment require large axial loads, large tilting moments and large radial loads, such as stacker-reclaimers, overweight transport machinery, port cranes, ladle turrets, shield tunneling machines, etc. Th...

-

Introduction to the assembly process of the slewing bearing

Publish time:2021-07-271.Slewing bearing parts inspection Check the appearance for bumps or rust spots. If there are serious bumps, rework treatment, check the shape and size, check whether the workpiece is consistent with the assembly drawing to avoid missing procedures and rework after assembly, carefully check the inner and outer ring raceways to find the soft area...

-

What materials are the parts of the slewing ring?

Publish time:2021-07-26The slewing ring is composed of inner ring, outer ring, rolling element, seal, cage, oil injection nipple and other parts. What we usually see is the finished slewing ring. What materials are used for the various parts of the slewing bearing? What are the characteristics of various materials? Unique Transmission will tell you one by one. ...

-

How to process the slewing bearing raceway after quenching?

Publish time:2021-07-26There are many types of raceways for slewing bearings. Four point ball slewing bearings have circular-arc raceways, crossed roller slewing bearings have right angle raceways, three row roller slewing bearings have flat raceways. There are generally two ways to process the raceways after quenching, grinding machining and CNC finish machining. Let...

-

What is the cause of the slewing ring damage?

Publish time:2021-07-25The slewing ring will be overloaded due to its own problems in use, unreliable sealing equipment, inadequate maintenance, etc will cause premature damage to the slewing ring raceway and rolling elements. The following are several reasons for the slewing ring damage. 1.Slewing bearing rings broken This situation often occurs on heav...

-

Introduction to the correct installation method of slewing ring

Publish time:2021-07-25Slewing ring is a very important transmission component in mechanical equipment. It has been widely used in various industries. When installing, you need to master the correct installation method to ensure the smooth operation of the equipment. Based on previous installation experience, we have summarized the essentials of installing slewing bea...

-

How often do you add grease to the slewing ring?

Publish time:2021-07-24The lubrication of the slewing ring generally uses grease, lithium-based grease is very commonly used. The most commonly used is No. 2 lithium based grease. According to the different working conditions of the slewing ring, such as temperature, speed, load, etc, also choose special greases, such as low temperature grease, high temperature grease...

-

How to choose the clearance of the spur gear slew drive?

Publish time:2021-07-23The clearance of a spur gear slew drive refers to the clearance of a slewing ring installed inside a spur gear drive, so how to choose the clearance of the spur gear slew drive? Before talking about this issue, we need to understand the definition of the clearance. Bearing clearance is the backlash between the rolling elements of the bear...

-

Which industries and equipment can the slewing ring be used in?

Publish time:2021-07-16Slewing rings have unique load capacity characteristics, usually used in hoisting machinery, excavators, rotary tables, wind generators, telescopes and tank turrets. Through the improvement of the processing method and the update of the design concept, the slewing ring can be used in smaller size, more complex structure and more precise occasion...

-

What material is the seal on the slewing ring?

Publish time:2021-07-16Sealing is a component that prevents fluid or solid particles from leaking between adjacent joint surfaces and prevents external impurities such as dust and moisture from intruding into the interior of machinery and equipment. Most rubber seals are made by compression molding, such as various extrusion seals, rotary shaft lip seals, recip...

-

U-TRSM introduces you to the heat treatment process of slewing bearings

Publish time:2021-07-16The slewing bearings need to go through multiple heat treatments during the production process, different heat treatments are carried out during the connection of each process to achieve the required heat treatment purpose. Heat treatment is the core part in the production of slewing bearings. Heat treatment determines the mechanical properties ...