Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail -

30855 slew drive assembly: precise protect...

30855 slew drive assembly: precise protect...Introduction In the field of industrial transmission, U-TRSM has always been a leader in innovation, committed...

Detailed instructions Send mail -

High load slewing drive solution for deep ...

High load slewing drive solution for deep ...This slewing drive is used in marine machinery and equipment, suitable for underwater locations at depths of up to 30...

Detailed instructions Send mail

Why is it not recommended to repair the gear after quenching and fracture in the slewing drive

Publish time:2023/12/07 News Views:242

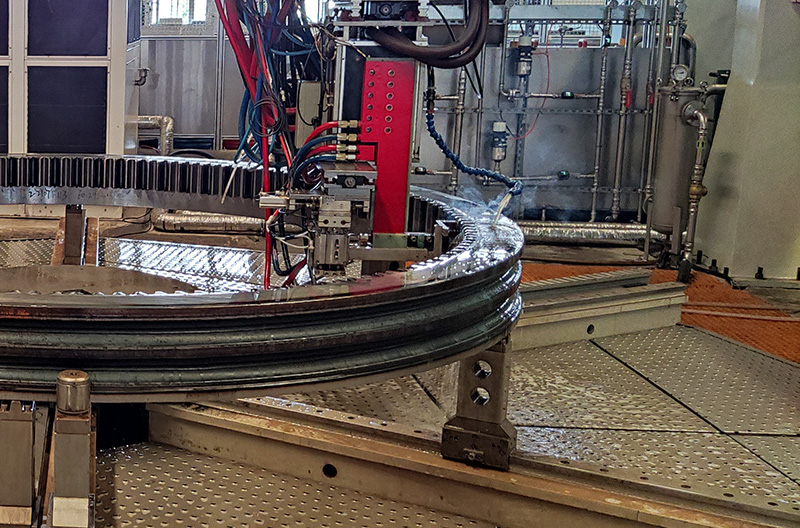

U-TRSM engineers are also involved in many processes during the production and machining of slewing drives and provide timely optimisation and feedback on details in order to design and produce quality products. As an accessory in a slewing drive, tooth hardening is a very critical process in the production of slewing bearings. Cracks may appear on the tooth surface if the tooth is not quenched properly, and after cracks are produced it is generally not recommended to weld them, but to scrap them directly. If cracked teeth are welded, the teeth will change as follows:

1. Changes in tensile strength: After welding, the tensile strength of the tooth will be reduced due to the stresses and deformations generated during the welding process, which will affect the load carrying capacity and service life of the tooth.

2. Changes in toughness: After welding, the toughness of the tooth will decrease, which will lead to the fracture of the tooth when it is impacted or vibrated greatly.

3. Changes in wear resistance: Welded teeth can suffer a loss of wear resistance due to factors such as the high temperatures and cooling that occur during the welding process, which can affect the life and efficiency of the tooth.

In order to avoid these changes adversely affecting the mechanical properties of the tooth, welding repair of the tooth is not recommended. If conditions do not permit, some measures can be taken to improve weld quality and minimise stress generation. For example, selecting appropriate welding materials and specifications, conduct preheating treatment and slow cooling after welding, etc. In addition, if a welding process is necessary, the appropriate tests and experiments should be carried out after the welding is completed.

- Introducing helical gears with different h...

- What are the commonly used types of slewin...

- Features of high precision same direction ...

- Why use thread fastening glue for spur gea...

- How to choose the external gear slewing dr...

- Backlash analysis of spur gear slew drive

- Analysis of the anti-corrosion design for ...

- What are the advantages of using 3D modeli...