Latest Products

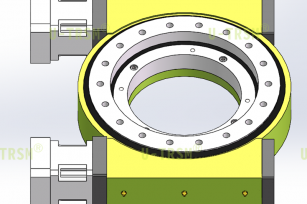

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Lightweight design and performance of U-TR...

Lightweight design and performance of U-TR...In the field of high speed automated mechanical equipment, the performance and light weight of the core drive compone...

Detailed instructions Send mail -

Analysis of lightweight double gear slew d...

Analysis of lightweight double gear slew d...Core Design Advantages In response to the core demands of limited installation space for automated rotating pl...

Detailed instructions Send mail -

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

-

Influence of rotational inertia on the slewing drive transmission performance

Publish time:2025-01-09The performance of the gear slewing drives designed and developed by U-TRSM is often affected by various external conditions. At the beginning of the design, we need to constantly communicate with the customer, have an overall and comprehensive understanding of the working conditions used by the customer, and design a high-quality solution for t...

-

How to choose the safety factor for slewing drives under different working conditions?

Publish time:2025-01-09In the design and manufacture of slewing drives by U-TRSM, the selection of a safety factor for the torque transmitted by the gears under different operating conditions is a complex and critical design consideration. The safety coefficient is directly related to the reliability and durability of the gear transmission system, U-TRSM design engine...

-

Why should there be a difference in tooth hardness between large and small gears in a slewing drive?

Publish time:2025-01-04In the process of designing slewing drives by U-TRSM, there is usually a difference in hardness between large and small gears on the gear transmission system, what is the significance of the existence of this hardness difference in practical applications? Below, the design engineers of U-TRSM will analyse a few points for your reference. ...

-

What is the impact of gear displacement design on transmission performance?

Publish time:2024-07-08In the process of designing the slewing drive structure, U-TRSM usually uses the meshing of large and small gears to transmit power and torque, and in some cases it is necessary to achieve the ideal requirements through the gear displacement. Through the reasonable displacement design, can achieve the effect of reducing the tooth surface contact...

-

What are the effects of gear radial runout on slewing drive?

Publish time:2024-05-21In the slewing drive structure designed and produced by U-TRSM, it is usually the large and small gears meshing to transmit power and torque. For the processing of gears, U-TRSM has rich experience, and different grades of gears can adapt to different working conditions of customers. The gear radial runout is an important indicator to verify the...

-

What is the difference between oil lubrication and grease lubrication for slewing drives?

Publish time:2024-04-24In the slewing drive design process, U-TRSM often encounter customers using oil lubrication conditions. In our standard design, many solutions are designed and manufactured in accordance with the grease lubrication, oil lubrication needs to improve the overall protection level of the slewing drive, this article will discuss the difference betwee...

-

Force rational design of integrated slewing drive

Publish time:2024-04-19U-TRSM has a wealth of technical experience in the design and manufacture of slewing drives, and often encounters designs in which the base and other components are integrated into the slewing drive. In addition to the slewing drive itself, the integrated external parts (frame or base), we will generally carry out a reasonable stress analysis, i...

-

What are the advantages of using 3D modeling to design slewing drives?

Publish time:2024-04-19At the beginning of its establishment, U-TRSM designed and manufactured slewing drive products based on 3D modeling. With the continuous development of Industry 4.0 and intelligent manufacturing, 3D modeling can improve the work efficiency of design engineers and quickly complete various complex design tasks. The functions such as 3D motion simu...

-

How to choose the external gear slewing drive or the internal gear slewing drive?

Publish time:2024-04-01The slewing drives designed and produced by U-TRSM can be divided into external gear slewing drives and internal gear slewing drives, how to choose these two types of slewing drives mainly depends on the requirements of the transmission system and the actual application scenarios, the following are a few considerations summarized by U-TRSM for y...

-

Analysis of the anti-corrosion design for slewing drive

Publish time:2024-03-25When designing slewing drives, U-TRSM engineers often encounter special requirements such as corrosion resistance and waterproofing. After many experiments and accumulated experience in design and production, we have been fully able to meet these needs. The working conditions of this type of slewing drive are generally bad, the environment is po...

-

How should the slewing drive be lubricated correctly?

Publish time:2024-02-27During the use of the slewing drive, selecting the appropriate lubrication method and ensuring sufficient lubrication can ensure the normal operation and use of the slewing drive and extend its service life. In the design phase of the slewing drive, the lubrication method can be determined according to the specific operating conditions, with the...

-

Analysis of the service life of the worm gear and worm meshing in the slewing drive

Publish time:2024-02-27Worm gear and worm slewing drive is a kind of reducer that can carry large loads. It is driven by the worm to rotate frictionally with the worm gear. During use, the service life of the worm gear and worm slewing drive is affected by the meshing between the worm and worm gear. So what are the factors that affect the service life of the worm gear...