U-TRSM double row ball slew drive: efficient load carrying solution for truck mounted cranes

Publish time:2025/08/11 Latest Products Views:76

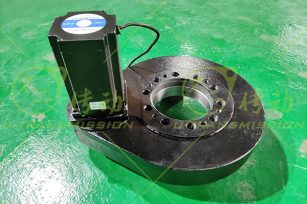

Model: WZ-Ⅵ-O-0478

Type: worm gear slew drive

Slew drive gear ratio: 80.0

Rotation center diameter: 478mm

Total height: 138mm

Gear backlash: ≤0.15mm

1. Design background and core requirements

The customer needs focus on the truck mounted crane scenario and the slew drive is required to meet the following:

Compact size: adapts to the space constraints of in-vehicle devices

High loads and tilting moments: to cope with complex force conditions in lifting operations.

U-TRSM has developed a double row ball slew drive for this purpose. Through the design of double row groove structure, it precisely solves the bottleneck of the traditional single row structure in terms of load capacity, and achieves a significant improvement in performance.

2. Technical highlights and performance parameters

The core advantages of the double row raceway design

Load capacity improve: the axial load can reach 3300kN, and the tilting moment can reach 315kN·m, which is more than 50% higher than the load capacity of a single-row structure.

Strong torque output: the rated output torque can reach 45kN·m, which meets the power needs of lifting equipment.

Stress dispersion and life extension: double row steel balls in the raceway to share the radial load, reduce the single-point stress concentration, reduce the fatigue damage of the raceway, and significantly extend the measured service life.

Synergistic optimisation of structure and performance

Compact space adaptation: the double-row ball structure achieves high load carrying capacity in limited radial space, which is suitable for the installation requirements of on-board equipment.

Motion accuracy guarantee: the raceway and the steel ball are precisely matched to ensure the smooth rotation movement, the positioning error is very small, and the operation safety is improved.

3. Application scenarios and customer feedback

Typical applications: truck-mounted cranes, slewing mechanisms for construction vehicles, mobile lifting equipment and other scenarios with strict space and load requirements.

Market feedback: with excellent load-bearing capacity, structural stability and durability, the slew drive has been well received by customers and has performed well in practical applications:

Improved work efficiency (high torque output reduces start-up lag)

Reduced maintenance costs (longer life, less frequent replacements)

Enhanced safety (improved anti-tilting capacity, reduced operational risk)

Summary

U-TRSM’s double row ball slew drive has achieved the technical breakthrough of “small volume and large load” through structural innovation, especially suitable for truck-mounted cranes and other scenarios that have double requirements for space and load. Its technical value lies not only in the improvement of parameters, but also in the optimisation of mechanical design, which balances the contradiction between equipment performance, service life and space limitation, and provides an efficient and reliable slew drive solution for the field of engineering equipment.