Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Lightweight design and performance of U-TR...

Lightweight design and performance of U-TR...In the field of high speed automated mechanical equipment, the performance and light weight of the core drive compone...

Detailed instructions Send mail -

Analysis of lightweight double gear slew d...

Analysis of lightweight double gear slew d...Core Design Advantages In response to the core demands of limited installation space for automated rotating pl...

Detailed instructions Send mail -

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

High speed double input copper worm gear slewing drive

Publish time:2023/08/26 News Views:298

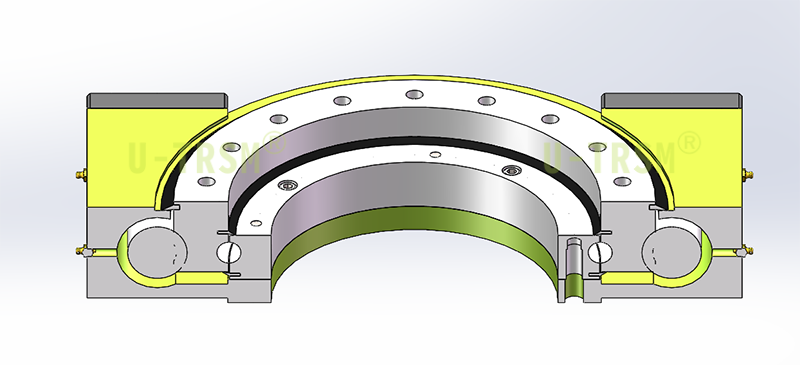

Unique Transmission Equipment (Luoyang) Co., Ltd. has designed a high precision double input high speed slewing drive for customers, which is used on automation equipment. Slewing drive adopts 0 clearance design to ensure the stability and accuracy in use, double input design greatly eliminates tooth backlash. Our customers use two servo motors to eliminate tooth backlash through control system, reducing the tooth backlash to almost 0. In this way, the rotational accuracy of the slewing drive can be better performed, and the worm gear is made of aluminum bronze material, which effectively improves the slewing drive rotational speed.

Slewing drive gear ratio: 86

Rated output speed: 10rpm

Rotation center diameter: 343mm

Total height: 108mm

Return clearance: ≤0.25mm

- What problems will affect the service life...

- Why is it not recommended to repair the ge...

- What material is the seal on the slewing r...

- How to reduce the slewing bearing gear noise?

- How could we increase the slewing bearing ...

- What are the similarities and differences ...

- Introduction to the correct installation m...

- Why use thread fastening glue for spur gea...