Latest Products

We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

-

Lightweight design and performance of U-TR...

Lightweight design and performance of U-TR...In the field of high speed automated mechanical equipment, the performance and light weight of the core drive compone...

Detailed instructions Send mail -

Analysis of lightweight double gear slew d...

Analysis of lightweight double gear slew d...Core Design Advantages In response to the core demands of limited installation space for automated rotating pl...

Detailed instructions Send mail -

Selection and characteristics of slewing d...

Selection and characteristics of slewing d...This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail -

Analysis of the high speed rotating double...

Analysis of the high speed rotating double...This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

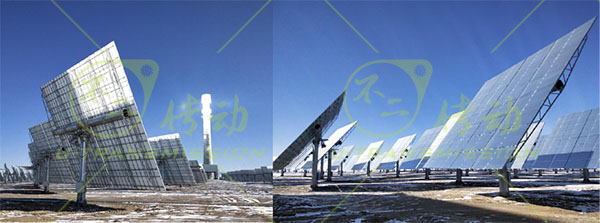

Application Analysis Of Slewing Bearing In Tower Photothermal Power Generation

Publish time:2021/07/12 News Views:771

Photothermal tower power generation refers to the installation of many large reflectors (heliostats) in the power station. Each heliostat is an independent unit, each equipped with a tracking mechanism, which can accurately reflect light to the top of the high tower in the center of the power station in real time. The molten salt is heated to 500-1000°C to convert solar energy into heat. The high temperature molten salt generates high temperature and high pressure steam through the steam generation system to drive the turbine generator unit to generate electricity. This is the working principle of solar thermal tower power generation.

There are a large number of heliostats in solar power, requiring real-time reflection of light to the heat absorber on the top of the tower. This requires constant adjustment of the azimuth and elevation angles when the heliostat is working. The pitch angle of the heliostat is adjusted with a linear actuator, the slewing bearing is used to support the entire heliostat rotating unit, at the same time is also responsible for adjusting the azimuth angle.

The height of the solar thermal tower power station is 200m, the radius of the heliostat site is 450m, the farthest linear distance from the heliostat to the heat absorber is nearly 500m. For such a long distance, if the heliostat produces a very small error when adjusting the azimuth angle, the error will be magnified by 1000 times when the reflected light reaches the heat absorber at the top of the tower. For example, when the heliostat adjusts the azimuth angle, the error is 1mm, the error when the reflected light reaches the heat absorber on the top of the tower will be 1000mm, that is 1m. When the heliostat adjusts the angle, the error must be very small. When the heliostat is stationary, it must be stationary, because shaking is detrimental to the work of the heliostat.

Heliostats require small rotation errors, stable at rest, used outdoors. These use requirements determine that the slewing bearings must have negative clearance ( there is no clearance between the inner ring and the outer ring), the starting torque is required to be very large (inner ring and outer ring). The starting torque requirements are very large (the interference between the inner ring and the outer ring is large), the finished product needs to be treated with anti-corrosion (to resist the rust generated during outdoor use). Such a slewing bearing can meet the requirements for the use of heliostats in tower power stations.

- Introduction to the advantages of finite e...

- Introduction to the connection mode of sle...

- Introduction to the assembly process of th...

- What factors need to be considered in the ...

- Introduction to the correct installation m...

- Analysis of the casting method of the slew...

- Causes and repairing methods of slewing ri...

- Why calculate and measure the starting tor...