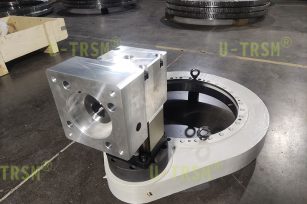

Lightweight dual-input industrial robot slewing drive

Publish time:2025/08/11 Latest Products Views:84

Model: S-I-O-0229-2

Type: gear type slewing drive

Slewing drive gear ratio: 61.0

Rotation center diameter: 229mm

Total height: 117.5mm

Gear backlash: ≤0.05mm

This slewing drive is used in industrial robot equipment. The customer requested a lightweight design with dual inputs, one for motor control and one for manual control, as well as precise positioning and positioning sensors are set on both sides of the slewing drive.

U-TRSM design engineers have developed this slewing drive based on customer requirements: the housing and adapter flange are made of aluminium alloy, and the slewing bearing is made thinner, reducing the weight from the standard model’s 50 kg to less than 37 kg, while ensuring that the load and output torque performance remain unchanged.

Dual-input gears are a common design in slewing drives and have widespread application in industrial automation equipment. The dual input design significantly increases the output torque of the slewing drive itself and achieves a complementary backlash-eliminating effect. For example, a symmetrical layout can offset axial thrust, reduce vibration and noise. They serve as mutual backups. If one gear fails unexpectedly, the other can still maintain partial power, enhancing the overall fault tolerance. Increasing the number of meshing teeth ensures uniform torque distribution, reduces impact, and reduces the risk of single-tooth fatigue, making it more suitable for frequent starts and stops or frequent speed changes.

The design of the dual input gear significantly improves the load capacity and stability of the slewing drive, making it suitable for heavy-duty or precision transmission applications with high reliability requirements.