Innovative design and application of high precision slewing drives in medical devices

Publish time:2025/08/06 Latest Products Views:81

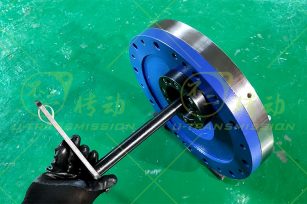

Model: S-Ⅳ-O-1632-OP

Type: gear type slewing drive

Slewing drive gear ratio: 10.47

Rotation center diameter: 1632mm

Total height: 180mm

Gear backlash: ≤0.15mm

1. Design background and customer needs

The customer’s medical equipment puts forward three core requirements for the slewing drive system:

Rotational smoothness: movement accuracy must be ensured during precision operations.

Low noise: suitable for quiet requirements in medical environments.

Limited installation space: the slewing drive system needs to be highly integrated to simplify the installation process.

2. Core design highlights and technical advantages

1) Space integration and structural optimisation

Crossed roller design: significantly improves the radial and axial load capacity of slewing drives in limited spaces, meeting the high load requirements of medical equipment.

Integrated rack base housing: through collaborative design with customers, the rack base and the slewing drive housing are integrated to reduce external connections and simplify installation.

Motor co-directional installation design: the motor installation surface and the rotated workpiece are located on the same side, shortening the transmission chain length, improving space utilisation, and avoiding disassembly and assembly interference.

2) Transmission accuracy and smoothness guarantee

Grade 6 precision gears: manufactured using high precision machining techniques, these gears feature low surface roughness and smooth torque transmission.

Small clearance and tooth clearance control: clearance 0-0.03 mm, tooth engagement clearance ≤ 0.10 mm, with preload design to eliminate backlash error and ensure rotational positioning accuracy.

End face runout control: end face runout ≤ 0.02 mm, ensuring axial stability during high speed rotation, suitable for dynamic operations of precision medical equipment.

3) Load capacity and reliability

| Parameter Type | Technical Specifications | Application Value |

| Axial Load | 3784Kn | Supports the rotation of heavy medical device components |

| Tilting Moment | 1100KN.m | Resists the risk of tilting caused by eccentric loads |

This slewing drive achieves multi-dimensional optimisation of load, precision and noise in space-constrained scenarios through its crossed roller structure, integrated design and high precision gear transmission. It not only meets the stringent requirements of medical devices, but also demonstrates the technological breakthroughs of high-end slewing drive components in the field of precision manufacturing. With the development of medical automation and intelligence, such high precision slewing drive systems will play a core role in more innovative equipment.