We keep on updating and iterating our products, optimizing the structural design and creating a more scientific and reliable slewing drive device.

This slewing drive is used in automated mixing equipment. The customer requires that it rotate in the same direction ...

Detailed instructions Send mail

This double row ball gear type slew drive is used in automation equipment. The customer requires ultra-high speed ope...

Detailed instructions Send mail

Introduction In the field of industrial transmission, U-TRSM has always been a leader in innovation, committed...

Detailed instructions Send mail

This slewing drive is used in marine machinery and equipment, suitable for underwater locations at depths of up to 30...

Detailed instructions Send mail

1. Design background and core requirements The customer needs focus on the truck mounted crane scenario and th...

Detailed instructions Send mail

This slewing drive is used in industrial robot equipment. The customer requested a lightweight design with dual input...

Detailed instructions Send mail

1. Design background and customer needs The customer’s medical equipment puts forward three core require...

Detailed instructions Send mail

This integrated slew drive is combined with a rotating platform. The customer requires the maximum load of the platfo...

Detailed instructions Send mail

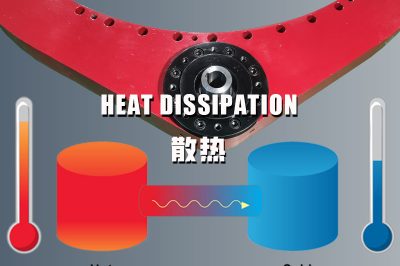

In the slew drive designed by U-TRSM, the core components are a combination of toothed slewing bearings and gears. Re...

Gear precision is a key factor affecting noise, and high precision gears can significantly reduce noise levels, the m...

In the field of industrial applications, the gear slew drives designed and produced by U-TRSM play a key role in many...

Among the slewing drives designed and manufactured by U-TRSM, worm gear slewing drives take up the vast majority. As ...

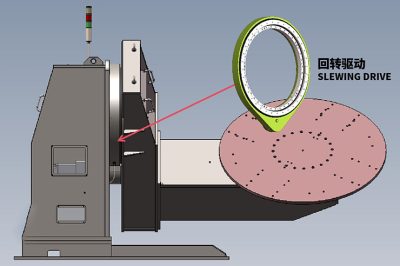

In modern welding production, welding positioner as a key equipment, plays a vital role. It can drag the workpiece to...

In the modern industrial field, slewing drive as a set of load capacity and deceleration function in one of the impor...

We are always improving ———–

Since we started to design and produce the first spur gear drive, optimization design and improvement plan are always in progress.

Contact usWe improve the processing technology of the housing, reduce processing cost, ensure the stability of the housing, the manufacturing process of the housing is not limited, can quickly and cheaply for customers to customize non-standard products to meet customers’ different use requirements.

We improved the sealing solution of the slewing drive to make the sealing of the slewing drive more reliable and the design is more reasonable, sealing guarantees high reliability of the slewing drive.

We improved the design of gears, unified and standardized the design of the input end to provide convenience for designing different solutions, reduce manufacturing costs, reduce the complexity of design and minimize the occurrence of errors.

Through repeated optimization design and scientific follow-up of the processing process, designers assemble and debug by themselves, form a mature and perfect design ideas and processing technology. Through continuous efforts, we have accumulated rich experience in design, processing, debugging and assembly, use 3D design software for modular design, which can quickly design solutions and solve problems for customers.