Lightweight design and performance of U-TRSM’s high speed slew drives

Publish time:2026/01/15 Latest Products Views:12

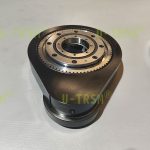

Model: S-P-I-0085

Type: spur gear slew drive

Slew drive gear ratio: 3.95

Rotation center diameter: 85 mm

Total height: 73 mm

Gear backlash: ≤0.10 mm

In the field of high speed automated mechanical equipment, the performance and light weight of the core drive components in equipment are becoming increasingly demanding. U-TRSM has a deep insight into the customer’s dual core demands for “high speed” and “light weight”, and through in-depth communication and collaborative research and development with the customer, we have successfully launched a high-performance slew drive suitable for this scenario, and at the same time has formed a mature lightweight design solution.

1. Customised high speed slew drive core advantages

For the special working conditions of high speed automation machinery and equipment, this slew drive achieves a comprehensive breakthrough in material selection, precision machining and performance parameters, the specific highlights are as follows:

Lightweight material, combining rigidity and weight reduction:

Key components such as the housing and flange are made of 6061-T6 aluminium alloy, which significantly reduces the overall weight of the slew drive and provides key support for the overall lightweight design of the equipment while ensuring that the structural rigidity meets the operational requirements of the equipment.

Precision process to guarantee operational accuracy:

Adopting the gear grinding process, the return clearance of the slew drive is accurately controlled to avoid transmission errors caused by excessive clearance in high speed operation and to improve the accuracy of the equipment movements.

The rotating parts are equipped with high precision crossed roller bearings, which not only meet the demand for high rotational speed of the equipment, but also effectively control the amount of rotational runout and further to ensure the stability and precision of the slew drive during high speed operation.

Excellent performance parameters for high load conditions

Based on a lightweight design, this slew drive still delivers a strong performance – the max speed can reach 588 rpm, the output torque can reach 200Nm, the axial load can reach 60KN, the tilting moment can reach 2KN. Meanwhile, its overall weight is only 6.3kg, achieving a perfect balance between “high performance” and “lightweight”.

2. Lightweight design for general solutions

In U-TRSM slew drive design and manufacturing practice, “light weight” is a common demand from many customers. In response to this need, our team has developed proven material substitution solutions:

Traditional standard design: the housings mostly use QT450-10 nodular cast iron, and flanges or shaft parts mostly use 45# steel, which can meet the basic strength requirements but the overall weight is relatively high.

Lightweight optimisation design: using 6061-T6 aluminium alloy to replace traditional cast iron and steel, it can reduce the overall weight of the slew drive by more than 30% while ensuring structural strength and meeting equipment operating load requirements, effectively adapting to the automation equipment scenarios that are sensitive to weight.

The P series in the U-TRSM catalogue is mainly designed for applications with high speed, high accuracy and relatively low load,generally operating at several hundred to over a thousand revolutions per minute, the axial and radial max precision can reach P2 level.